Product Description:

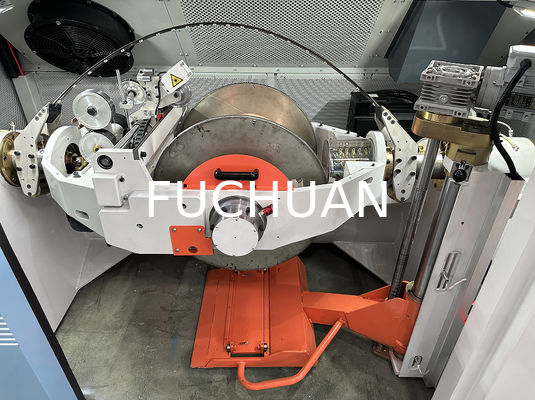

The Copper Wire Bunching Machine, also known as a Copper Wire bunching Machine, Copper Wire Stranding Machine, or Copper Wire buncher twisting Machine, is a powerful industrial equipment designed for efficiently bunching copper wires together. This machine is equipped with a high-performance 15KW AC Servo Motor as its main motor, ensuring reliable and consistent operation.

One of the key features of this Copper Wire Bunching Machine is its ability to twist wires in either the S or Z direction, providing flexibility in wire bunching configurations. Whether you require clockwise (S) or counterclockwise (Z) twisting, this machine can handle your specific needs with precision.

With a maximum cross-section capacity of up to 6.0 square milimeter, this machine is suitable for handling a wide range of copper wire sizes and types. The robust construction and advanced technology of this machine enable efficient bunching of wires while maintaining quality and consistency in the final product.

The Copper Wire Bunching Machine comes with a spool size of Φ630mm, allowing for the efficient winding and unwinding of wire during the bunching process. This large spool size minimizes downtime for spool changes and ensures continuous operation for increased productivity.

As a testament to its quality and reliability, this machine is backed by a comprehensive 1-year warranty, providing you with peace of mind and assurance of its durability and performance. In the rare event of any issues or defects, you can rely on the warranty coverage to support the maintenance and repair of your Copper Wire Bunching Machine.

Features:

- Product Name: Copper Wire Bunching Machine

- Warranty: 1 Year

- Fit Copper Wire: 0.12mm To 0.45mm

- Also Wire: Enamelled Wire / Bare Copper Wire

- Stranding Section Area: 0.35-6.0mm2

- Weight: 4000KG

Technical Parameters:

| Fit Copper Wire |

0.12mm To 0.45mm |

| Plate |

Aluminum Plate |

| Control System |

PLC |

| Twist Direction |

S Or Z |

| Fit For Wire |

Bare Copper Wire |

| Weight |

4000KG |

| Voltage |

380V |

| Cross Section |

Max To 6.0 Square Milimeter |

| Also Wire |

Enamelled Wire / Bare Copper Wire |

| Finish |

Tempering And Grinding |

Applications:

The Fuchuan Copper Wire Bunching Machine is a high-quality and efficient machine designed for various wire bunching applications. With models such as FC-300, FC-400, FC-500, FC-650B, FC-800B, FC-652D, FC-653D, and FC-1250C, this machine is a versatile solution for wire stranding, interweaving, and grouping.

Originating from China, this Copper Wire Bunching Machine is suitable for handling both enamelled wire and bare copper wire. Its robust construction ensures a weight of 4000KG, making it a reliable choice for heavy-duty wire bunching tasks.

Equipped with a spool size of Φ630mm and the capability to work with wire cross-sections of up to 6.0 square milimeters, this machine offers exceptional flexibility for various wire bunching requirements. Its fully automatic operation further enhances efficiency and productivity, making it a valuable asset for wire manufacturing processes.

The Fuchuan Copper Wire Bunching Machine is ideal for a wide range of product application occasions and scenarios. Whether in the automotive, electrical, or telecommunications industries, this machine excels in producing high-quality wire bunching results with precision and consistency.

Whether you need a Copper Wire Stranding Machine, Copper Wire Interweaving Machine, or Copper Wire Grouping Machine, the Fuchuan Copper Wire Bunching Machine delivers excellent performance across different wire bunching applications.

Customization:

Product Customization Services for the Copper Wire Bunching Machine:

Brand Name: Fuchuan

Model Number: FC-300/400/500/650B/800B/652D/653D/1250C

Place Of Origin: China

Spool Size: Φ630mm

Voltage: 380V

Fit Copper Wire: 0.12mm To 0.45mm

Plate: Aluminum Plate

Control System: PLC

Support and Services:

The Copper Wire Bunching Machine is designed to efficiently bunch and twist multiple copper wires together to create a single, uniform cable. Our product technical support team is available to assist with any troubleshooting, maintenance, or operational questions that may arise during the use of the machine.

In addition to technical support, our services include installation guidance, training for machine operation, and regular maintenance check-ups to ensure optimal performance and longevity of the equipment.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!