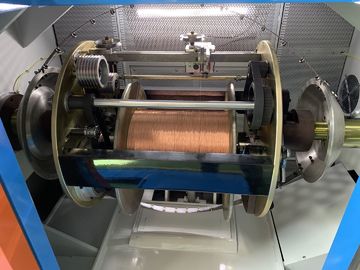

Stable Copper Wire Twisting Machine , Wire Pay Off Machine 3000 RPM

Merits:

1. Over-line system: The latest structure, the wire from the spindle directly across the guide wheel to the bow belt, the bow (with) a unique semi-circular groove design, with the bow with a semicircle porcelain ring line to avoid high-speed operation due to wind resistance Caused by stranding scratch, jump shares phenomenon

2. Spindle lubrication: butter lubrication (Oil lubrication defects: the oil’s temperature increases while high-speed operation , and the oil mist will concentrate into beads on the wall , falling to the reel and pollute the conductor, cause blister when conduct insulating )

3. Security protection: If the door contact is not in place, lift contact is not in place, internal and external wire broken error display in the touch screen on the automatic alarm or can not start to work

4. Transmission system: drive with synchronous belts , laying accurate, no internal lubrication position, no waste products effect by refueling and machine cleaning

5. Change the lay length: easy to operate, just change the leading wheel according to the lay length sheet

6. Pressing device: equipped with two pressing devices to ensure the roundness of the conductor after twisting, to protect the product characteristics of thin-walled insulation line, effectively reduce the wear and tear of insulating materials.

7. Meter counting way: the latest domestic design, with spindle meters; the same machine twisted with a conductor specifications, meter error in one ten thousandth

Copper Wire Twisting Machine Detail Specification:

| Description |

Model |

Origin |

| 1.Host Motor |

2.2KW-4P 380V 50Hz |

SIEMENS |

| 2.Inverter |

2.2KW |

INOVANCE |

| 3.PLC Programmer |

32MR |

INOVANCE |

| 4.PLC Expander |

VB-3A |

INOVANCE |

| 5.Touch Screen |

7 inches RGB |

WEINVIEW |

| 6.Electromagnetic Brake |

6KG |

Tai Wan Weizheng |

| 7.Magnetic Clutch |

0.05KG |

Japan OPC |

| 8.Spindle Bearings |

1SET |

SWEDEN SKF |

| Other Bearings |

1SET |

JAPAN NSK |

| 9.Timing Belt |

1SET |

US GATES |

| 10.Cable Laying Device |

GP20(Special bi-direction) |

SHANXI Tianxiang |

| 11.Tension Controller |

WLK-0.5A |

TAIWAN |

| 12.Bow |

1SET |

Japan |

| 13.Body |

1SET |

Self-processing |

| 14.Spindle |

2pcs |

Self-processing |

| 15.Aluminum Plate |

2pcs |

Self-processing |

| 16.Timing Pulley |

1SET |

Wu Xi |

| 17.Bearing Housings |

1SET |

Self-processing |

| 18.Disc |

2pcs |

Self-processing |

| 19.Transmission Shaft |

1pcs |

Subcontracting |

| 20.Leading Wheel |

1SET |

Self-processing surface with hard chrome plating |

| 21.Wire guide wheel |

6pcs |

Self-processing surface with hard chrome plating |

Spare parts sheet

| No. |

Description |

Model |

Qty |

Remark |

| 1 |

Operating instructions |

|

1SET |

|

| 2 |

Electrical Schematic |

|

1SET |

|

| 3 |

Inverter manual |

|

1pcs |

|

| 4 |

Spindle guide wheel |

Φ46(with 696 ZZ Bearings) |

1SET |

|

| 5 |

Wire guide wheel |

Φ34(693AZZ Bearings) |

1SET |

|

| 6 |

Loops in Bow |

Bilateral porcelain ring |

3pcs |

|

| 7 |

Split plate porcelain ring |

Φ4.0 |

3pcs |

|

| 8 |

Stranded Die |

None |

|

|

| 9-11 |

Timing belt |

5M-450*10 |

1pcs |

|

| 12 |

Spool Top sleeve |

Φ200 spool |

1SET |

|

| 13 |

SKF Butter |

LGMT2/1 |

1

Bottle

|

1KG |

| 14 |

Grease gun |

|

1pcs |

|

| 15 |

Tool |

|

1SET |

|

Mechanical Performance

1. Body structure:

1) Material: low carbon steel welded together.

2) Structure: the body by annealing and aging, to eliminate internal stress, and then boring by a precision boring machine to forming a molding.

2. Bunching Entry part:

1) Bunching Entry position: facing to the front door, at the right side of the machine (can be customization according to customer requirements to change to the left side).

2) Bunching Entry Mode : from the pay-off device through the disconnection sensing area, first to the total sub-line board (sub-hole by 1 +6 +12 + ... distribution), through first pressure mold, then the second Pressure mold, after entering the right spindle within the wire guide wheel. From the aluminum arch with porcelain ring and then into the left spindle within the wire guide wheel, and then through the center corner’s guide wheel to the leading wheel, Final to the aligner’s guide wheel to cable laying (see wire bunching entry pattern diagram)

3. Spindle:

1) Material: 40Cr steel forging after quenching and tempering treatment.

2) Accuracy: The shaft core outer face diameter and the bearing end face are ground to ensure concentricity and verticality with the axis.

3) Dynamic balance: Standard of G2.5 (0.03 grams of weight difference)

4. Aluminum plate:

1) Material: ZL104

2) Accuracy: All end faces are positioned relative to the locating holes(less than 0.03 grams)

3) Dynamic balance: Accuracy of G2.5 (0.03 grams of weight difference)

5. Bow

1) Material: Japan imported SK5.

2) Shape: special appearance, reduce the wind resistance.

3) Weight tolerance : less than 0.03 grams per pair

6. Transmission part: with imported synchronous belt drive, laying length accurate

7. Wire entry wheel:

1) Material: # 45 steel finished with heat treatment HRC30-40.

2) Hard chrome plated on the surface, not easy to wear

8. Spindle housing:

1) Material: ductile iron QT42-10.

2) Processing: CNC machine tooling

3) Accuracy: one processing hole end molding, to ensure concentricity.

9. Spindle bearing lubrication system:

1) Lubrication method: butter lubrication

2) Butter Model: LGMT2

3) Sealing method: mechanical oil retaining ring, keep the machine clean inside

10.Take up:Tensile tension control: through the magnetic clutch control thread tension, by the PLC program controller automatically adjust the tension, keep tension constant

11. Cable laying:Special two-way cable laying device, φ15mm light rod bearing type,lay length and distance can be accurately adjusted

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!