Product Description:

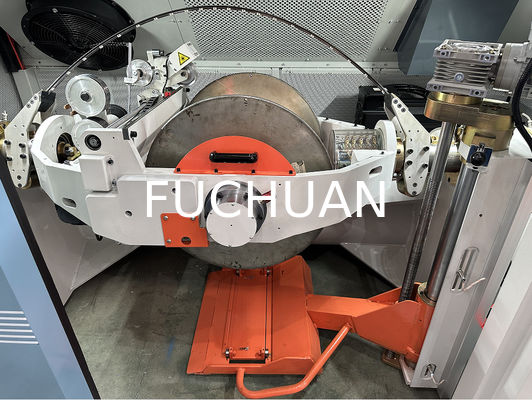

The Copper Wire Bunching Machine is a highly efficient and reliable piece of equipment designed for wire production processes. With a warranty of 1 year, you can trust in the quality and durability of this machine to meet your production needs.

One of the key advantages of this Copper Wire Bunching Machine is its fully automatic operation. This feature not only enhances productivity but also ensures consistent and precise wire bunching results. The machine is equipped to handle various wire types, including Enamelled Wire and Bare Copper Wire, making it versatile for different production requirements.

The stranding section area of the machine ranges from 0.35mm2 to 6.0mm2, providing flexibility in handling different wire sizes with ease. This capability allows for increased efficiency and customization in wire production processes.

Operating at a voltage of 380V, the Copper Wire Bunching Machine is designed to deliver powerful performance while maintaining energy efficiency. The machine is engineered to meet industry standards and requirements, ensuring reliable and safe operation in various production environments.

Whether you are in the market for a Copper Wire Bundling Machine, a Copper Wire Stranding Machine, or a Copper Wire Twisting Machine, this versatile equipment is equipped to handle your wire production needs effectively. Its automatic operation, wide stranding section area, and compatibility with different wire types make it a valuable asset for any wire manufacturing facility.

Features:

-

Product Name: Copper Wire Bunching Machine

-

Main Motor: 15KW AC Servo Motor

-

Control System: PLC

-

Twist Direction: S Or Z

-

Fit Copper Wire: 0.12mm To 0.45mm

-

Finish: Tempering And Grinding

Technical Parameters:

|

Fit Copper Wire:

|

0.12mm To 0.45mm

|

|

Weight:

|

4000KG

|

|

Warranty:

|

1 Year

|

|

Twist Direction:

|

S Or Z

|

|

Control System:

|

PLC

|

|

Main Motor:

|

15KW AC Servo Motor

|

|

Plate:

|

Aluminum Plate

|

|

Advantage:

|

Fully Automatic

|

|

Finish:

|

Tempering And Grinding

|

|

Also Wire:

|

Enamelled Wire / Bare Copper Wire

|

Applications:

Manufactured in China, the Fuchuan Copper Wire Bunching Machine comes in several models including FC-300, FC-400, FC-500, FC-650B, FC-800B, FC-652D, FC-653D, and FC-1250C. This equipment is specifically designed to handle copper wires ranging from 0.12mm to 0.45mm in diameter, making it ideal for a variety of applications.

The main motor of this Copper Wire Intertwining Machine is a powerful 15KW AC servo motor, providing the necessary strength and precision for efficient wire bunching. With a voltage requirement of 380V, this machine can be easily integrated into different industrial setups.

One of the key features of the Fuchuan Copper Wire Bunching Machine is its ability to twist wires in either the S or Z direction, offering flexibility and customization options for different production needs. Additionally, this machine boasts a fully automatic operation, providing convenience and efficiency in wire bunching processes.

The Fuchuan Copper Wire Bunching Machine is suitable for a wide range of scenarios, including cable manufacturing, electrical wiring production, and telecommunications industry applications. Whether in a factory setting or a production facility, this machine can streamline wire bunching operations and improve overall productivity.

Customization:

Product Customization Services for the Copper Wire Bunching Machine:

Brand Name: Fuchuan

Model Number: FC-300/400/500/650B/800B/652D/653D/1250C

Place Of Origin: China

Spool Size: Φ630mm

Warranty: 1 Year

Fit For Wire: Bare Copper Wire

Also Wire: Enamelled Wire / Bare Copper Wire

Voltage: 380V

Support and Services:

The Copper Wire Bunching Machine product comes with comprehensive Product Technical Support and Services to assist customers with any issues or inquiries they may have. Our dedicated technical support team is available to provide guidance on machine operation, troubleshooting, and maintenance. Additionally, we offer training services to ensure that customers are equipped with the necessary knowledge and skills to operate the machine efficiently.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!